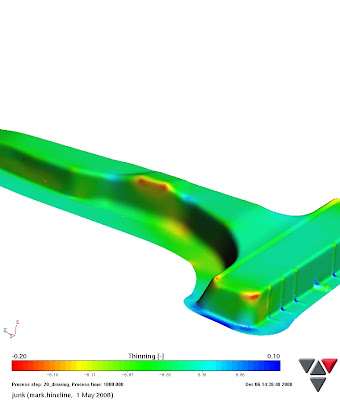

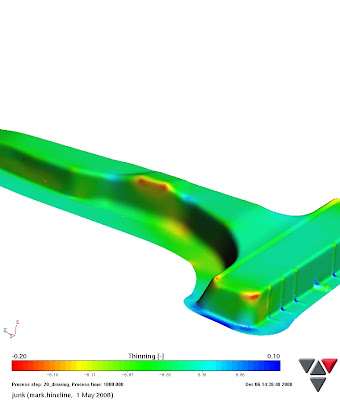

The starting thickness of your sheet metal call that s and the formed thickness of your part at the location of interest call that f.

Sheet metal thinning standard.

The equivalent thicknesses differ for each gauge size standard which were developed based on the weight of the sheet for a given material.

It is easy to work with and very attractive in the home.

Plain metal sheets of architectural quality vary in thickness between 025 60 mm and 124 3 mm.

X 36 the md building products 36 in.

Just as any other high traffic and high wear application the specifier needs to consider minimum thickness to avoid denting.

Sheet metal is the next in line.

Yielding occurs when σeffective y.

Gauge differs between ferrous iron based metals and nonferrous metals such as aluminum or copper.

Material taken from metal forming by hosford and caddell.

Shear press lmp shop.

Commonly used steel sheet metal ranges from 30 gauge to about 7 gauge.

The larger the gauge number the thinner the metal.

In deep drawing manufacture if the clearance is too small the sheet may be cut or pierced not well despite the radius.

The thickness of sheet metal starts from 0 5 mm and goes up to 6 mm.

In the u s the thickness of sheet metal is commonly specified by a traditional non linear measure known as its gauge.

The percent thinning is calculated as t 100 s f s.

If you have accurate measurements you can have confidence in your results.

Astm e517 standard test method for plastic strain ratio r for sheet metal governs its determination.

Sheet metal gauge size chart gauge or gage sizes are numbers that indicate the thickness of a piece of sheet metal with a higher number referring to a thinner sheet.

F 0 7 t l uts t sheet thickness l total length sheared uts ultimate tensile strength of material.

Anything above that is a metal plate.

The thin sheet metal is easy to form while still providing great strength.

Mill aluminum union jack style perforated sheet metal offers a decorative way to complete your hvac door window hobby and cabinet projects.

Clearance in deep drawing manufacture is greater than sheet thickness usually clearance values are 107 to 115 of sheet thickness.

In cutting operations is relatively small usually 3 to 8 of sheet metal thickness.

The plastic strain ratio r indicates the ability of the sheet metal to resist thinning or thickening when being deep drawn into a cup for example the r value is calculated from width and longitudinal strain and is a measure of sheet metal drawability.

The sheet features a union jack style perforated design.

That is why we see it everywhere around us.

Elevator surfaces such as doors and cab wall facings are usually specified in 18 gauge 0 050 or 1 20 mm.

At this point you have two measurements.